A FERRARI STORY: Maria Assunta di Rossi-Ledesma Dares to Dream (2nd of 3 Parts)

Text and photos by Jules Ledesma IV

|

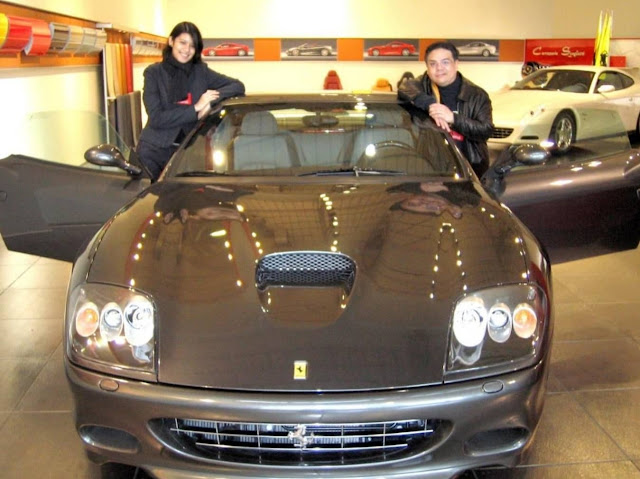

| My wife Ma. Assunta, and I with our new baby, a Ferrari Superamerica we named Sophia. |

A FERRARI IS...

State of the art. Be it in design, materials, engineering, systems and where applicable manufacture. And yet, at the engines, power train and unit final assembly; hand built by artisans. Third millennia design, engineering, and materials, Renaissance era craftsmanship... you pay for what you get.

Initially oxymoronic thoughts first few minutes of the tour, these impressions soon were digested the further we moved along. High-tech-handcrafted...engineers-artisans...mass-produced low volume...robotics array-hand assembled...alcoa aluminiumpoltrona hides...laser cut hides- handheld glue guns. Cad/cam/cnc. - hand-buffed, hand-fitted, hand-finished.

It became immediately obvious that technology, be they robotics or other devices were used as appropriate. The system of parts and systems of logistics are thoroughly modern and yet HAND FITTED in all stages. The lines and the support systems are state of the art.

Every component can, and is assigned and prepared to THE INDIVIDUAL UNIT, likewise from a systems flow, everything can be monitored individually, by unit, by group, by line and finally in totality. Small isn’t necessarily archaic, and simple doesn’t mean unsophisticated. Handcrafted doesn’t have to be crude.

From the engine assembly lines to the chassis, and substructure assembly to the body and interiors, and through final assembly, you could trace from sub-frame, to engine mating, on to the body & panel line. It was anachronistic & schizoid to see hand operated sewing and stitching machines, robot- glue guns, and hide stretching and fitting machines all in an inner bay.

There was even a system for the way the looms and the threads were arrayed and hides stacked, which and for what the respectively assigned and LASER pre-cut hides would be hand machine stitched and sheathed on seats, panels, and dash.

Impressive is an understatement. Gloriously redolent aroma and when you see a RECARO stamp on the seat assembly you know that your back is ‘covered’.

Oxymoronic, dysfunctional, operationally conflicted? Actually NO. The seemingly systematic chaos, is in fact an Integrated Organism. A SYSTEM AND PROCESS OF MANUFACTURE. One sees, slowly grasps, finally admires, FERRARI’S version of TOYOTA’S moving line assembly. The very same principle also used by Boeing and the aerospace industry. Only when you’ve walked through the ‘line’ will you be awed by the sense of it all. It’s almost, it’s a quarter past two, I’d been checking every so often.

"Can we go see our car now...... ...please....... can we go see our car now..."

The Delivery Hall

At around a quarter past two we entered the... ‘Delivery Hall’. Lucia, our personal guide, and assigned to sales- Asia Pacific. Ms. Agnes Ng who flew in for this, and 2 Ferrari tech staff who would walk us through some of the major –to do’s- must knows & the Ferrari paparazzi. Finally Chris Baio Area Manager, Maria Assunta and I. And... ‘Sophia’...

‘Sophia’ captures the Superamericas’ essence... Discreet heat.

...and then it was time...

To be continued

Share in

.jpg)